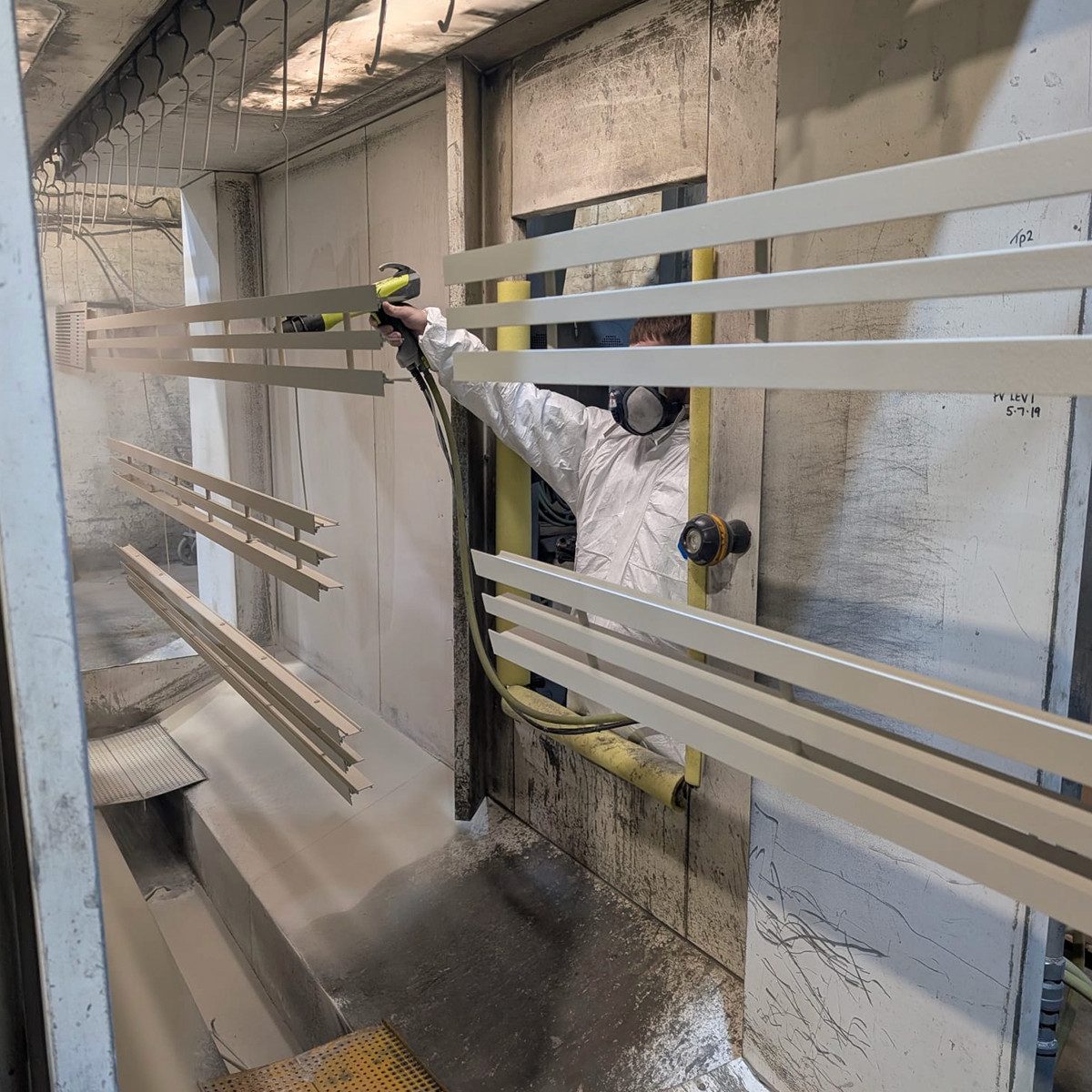

Pre-Treatment

Zirconium Phosphate Pre-Treatment

Prepare your metal surfaces for flawless powder coating with our advanced zirconium phosphate pre-treatment services in Stoke-on-Trent. Using cutting-edge technology and eco-friendly solutions, we optimise surface adhesion and corrosion resistance, ensuring that your powder coating achieves a smooth, durable, and professional finish every time.

Why Pre-Treatment Is Essential for Powder Coating

Effective pre-treatment is the foundation of any durable powder coating. Our zirconium phosphate process cleans and primes metal surfaces, ensuring superior powder coating adhesion while extending the life and performance of the finish. This step is crucial for achieving a seamless application that resists chipping, corrosion and wear over time.

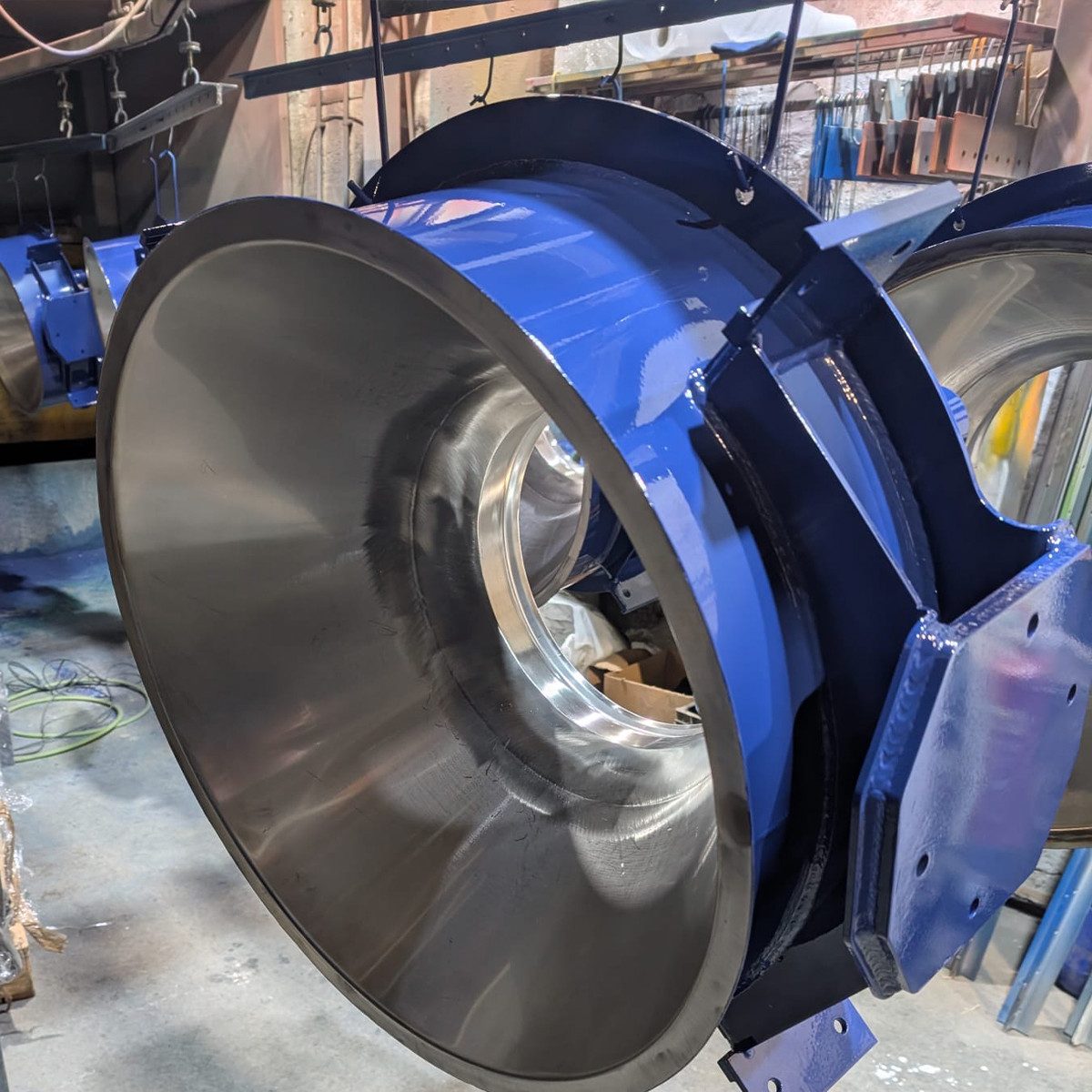

Solutions for Large & Small Components

Our facility is equipped to handle components of all sizes, thanks to a 3-metre diameter capacity basket and a lance attachment for pre-treating larger or irregularly shaped items. Whether you’re preparing industrial parts, automotive components, or architectural features for powder coating, we deliver consistent, high-quality results.

Three-Stage Pre-Treatment Process for Powder Coating

- Hot Washing with Natech ZPSL:

A specially formulated zirconium phosphate solution that creates a lightweight conversion coating on materials like iron, steel, aluminium, and zinc. This prepares the surface for optimal powder coating adhesion. - Hot Rinsing:

A water-based rinse with synergic detergent additives eliminates impurities, ensuring a pristine surface for powder coating. - Hot Passivation Solution:

The final rinse uses Kolseal MO, a non-chromated sealant that improves corrosion resistance and enhances the bond between the metal and the powder coating.

Environmentally Friendly Pre-Treatment for Powder Coating

Natech ZPSL represents the next generation in sustainable surface preparation. Designed specifically for pre-treatment before organic coatings like powder paint, this eco-conscious solution delivers:

- Enhanced corrosion resistance with up to 1,000 hours of salt spray durability on steel and up to 3,000 hours on aluminium.

An alternative to traditional chrome and zinc phosphating methods. - Compatibility with all types of powder coating, including electrostatic spray and fluidised bed techniques.

- By choosing our zirconium phosphate pre-treatment, you benefit from a process that’s both effective and environmentally responsible.

Powder Coating Pre-Treatment Specialists in Stoke-on-Trent

Powder Coating Pre-Treatment Specialists in Stoke-on-Trent

Situated in Stoke-on-Trent, we are trusted experts in pre-treatment for powder coating. From thorough cleaning to creating the perfect surface for coating adhesion, our zirconium phosphate process ensures your powder coating exceeds expectations in appearance, durability, and longevity.